Specification, Bitumen Tests, and Properties of Bitumen

Bitumen is a complex material with a complex response to stress. All bitumens show a more or less pronounced viscoelastic behavior. their resistance to deformation being dependent on both the temperature and time during which a force is applied. Only under extreme conditions can a bitumen behave either as a typical elastic solid (low temperature very short loading time) or as a viscous liquid (high temperature, long loading time). Under normal temperature conditions, both viscous and elastic behavior play their part. Since both temperature and loading time are variable under the conditions of practice. The temperature and time susceptibilities of bitumen are important performance factors. In order to characterize the numerous bitumen grades a number of test methods have been developed. Initially, these tests aimed at measuring an arbitrary mechanical property which made it possible to discriminate between various bitumens. The limits between which such properties had to be well known from practical experience. Examples of such methods of characterization and their appropriate consistency are:

– Fraass breaking point

- brittleness

- Penetration

- semi-solid range

- Softening point

- the beginning of fluidity

- Viscosity fluidity range

- Penetration Index

- temperature susceptibility

There are no universally accepted specifications for bitumen, cutback bitumen, or bitumen emulsions. The text here discusses specifications in relation to the relevant British Standards: however, other bitumen specifications are acknowledged to be equally valid, differing only in the specification tests detailed or the test ranges for the various different grades. In Europe, the national specifications for bitumen are in the process of being consolidated into a unified CEN specification, whilst in much of the world, the ASTM specifications are commonly used. Most bitumen specifications have a degree of commonality centering around the use of penetration and softening point values, whilst the remaining specification properties vary.

Bitumen Standards Specification Tests

As an almost infinite variety of bitumens can be manufactured, it is necessary to have tests which can characterize different grades. The two principal tests used most frequently to characterize bitumens are penetration and softening point. These two tests are used to specify different grades of bitumen. Although they are arbitrary empirical tests, it is possible to estimate from them important engineering properties, such as high-temperature viscosity and low-temperature stiffness. The use of the penetration test for characterizing the consistency of bitumen dates from the late 19th century. As the penetration and softening point tests are empirically derived it is essential that they are always carried out under exactly the same conditions. The Institute of Petroleum (IP), the American Society for Testing and Materials (ASTM). and British Standards (BS) publish standard methods for testing bitumen. In many cases the methods are identical and therefore methods are published jointly. However, some methods differ in detail, for example, the IP and ASTM softening point method, and in these cases, a correction factor must be applied to relate test results obtained using these two test methods. The majority of the methods quote limits for assessing the acceptability of test results. Precision data for results obtained by a single operator (repeatability) and by different operators in different laboratories (reproducibility) are specified. Thus tolerance is given to allow for differences between operators and equipment at different locations.

Bitumen Tests

There are a number of tests to assess the properties of bituminous materials. The following tests are usually conducted to evaluate different properties of bituminous materials.

- Penetration test

- Ductility test

- Softening point test

- Specific gravity test

- Viscosity test

- Flash and Fire point test

- Float test

- Water content test

- Loss on heating test

Bitumen Tests- Penetration Test

It measures the hardness or softness of bitumen by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically in 5 seconds. BIS had standardised the equipment and test procedure. The penetrometer consists of a needle assembly with a total weight of 100g and a device for releasing and locking in any position. The bitumen is softened to a pouring consistency, stirred thoroughly and poured into containers at a depth at least 15 mm in excess of the expected penetration. The test should be conducted at a specified temperature of 25 C. It may be noted that penetration value is largely influenced by any inaccuracy with regards to pouring temperature, size of the needle, weight placed on the needle and the test temperature. A grade of 40/50 bitumen means the penetration value is in the range 40 to 50 at standard test conditions. In hot climates, a lower penetration grade is preferred. Figure 0.1 shows a schematic Penetration Test setup.

Bitumen Tests- Ductility Test

Ductility is the property of bitumen that permits it to undergo great deformation or elongation. Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking. The dimension of the briquette thus formed is exactly 1 cm square. The bitumen sample is heated and poured in the mould assembly placed on a plate. These samples with moulds are cooled in the air and then in the water bath at 27 C temperature. The excess bitumen is cut and the surface is leveled using a hot knife. Then the mould with the assembly containing sample is kept in the water bath of the ductility machine for about 90 minutes. The sides of the moulds are removed, the clips are hooked on the machine and the machine is operated. The distance up to the point of the breaking of thread is the ductility value which is reported in cm. The ductility value gets affected by factors such as pouring temperature, test temperature, the rate of pulling etc. A minimum ductility value of 75 cm has been specified by the BIS. Figure 0.1 shows ductility moulds to be filled with bitumen.

Bitumen Tests- Softening Point Test

Softening point denotes the temperature at which the bitumen attains a particular degree of softening under the specifications of test. The test is conducted by using Ring and Ball apparatus. A brass ring containing test sample of bitumen is suspended in liquid like water or glycerin at a given temperature. A steel ball is placed upon the bitumen sample and the liquid medium is heated at a rate of 5 C per minute. Temperature is noted when the softened bitumen touches the metal plate which is at a specified distance below. Generally, higher softening point indicates lower temperature susceptibility and is preferred in hot climates. Figure 0.1 shows Softening Point test setup.

Bitumen Tests- Specific gravity Test

In paving jobs, to classify a binder, density property is of great use. In most cases, bitumen is weighed, but when used with aggregates, the bitumen is converted to volume using density values. The density of bitumen is greatly influenced by its chemical composition. Increase in aromatic type mineral impurities causes an increase in specific gravity.

The specific gravity of bitumen is defined as the ratio of the mass of given volume of bitumen of known content to the mass of the equal volume of water at 27 C. The specific gravity can be measured using either pycnometer or preparing a cube specimen of bitumen in the semi-solid or solid state. The specific gravity of bitumen varies from 0.97 to 1.02.

Bitumen Tests- Viscosity Test

Viscosity denotes the fluid property of the bituminous material and it is a measure of resistance to flow. At the application temperature, this characteristic greatly influences the strength of resulting paving mixes. Low or high viscosity during compaction or mixing has been observed to result in lower stability values. At high viscosity, it resists the compactive effort and thereby resulting mix is heterogeneous, hence low stability values. And at low viscosity instead of providing a uniform film over aggregates, it will lubricate the aggregate particles. Orifice type viscometers are used to indirectly find the viscosity of liquid binders like cutbacks and emulsions. The viscosity expressed in seconds is the time taken by the 50 ml bitumen material to pass through the orifice of a cup, under standard test conditions and specified temperature. The viscosity of a cutback can be measured with either 4.0 mm orifice at 25$^o$ C or 10 mm orifice at 25 or 40 C.

Bitumen Tests- Flash and Fire Point Test

At high temperatures depending upon the grades of bitumen, materials leave out volatiles. And these volatiles catches fire which is very hazardous and therefore it is essential to qualify this temperature for each bitumen grade. BIS defined the flash point as the temperature at which the vapour of bitumen momentarily catches fire in the form of flash under specified test conditions. The fire point is defined as the lowest temperature under specified test conditions at which the bituminous material gets ignited and burns.

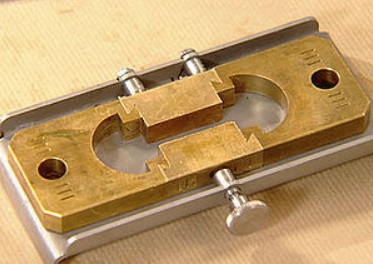

Bitumen Tests- Float Test

Normally the consistency of bituminous material can be measured either by penetration test or viscosity test. But for certain range of consistencies, these tests are not applicable and Float test is used. The apparatus consists of an aluminum float and a brass collar filled with bitumen to be tested. The specimen in the mould is cooled to a temperature of 5 C and screwed in to float. The total test assembly is floated in the water bath at 50 C and the time required for water to pass its way through the specimen plug is noted in seconds and is expressed as the float value.

Bitumen Tests- Water Content Test

It is desirable that the bitumen contains minimum water content to prevent foaming of the bitumen when it is heated above the boiling point of water. The water in a bitumen is determined by mixing known weight of specimen in a pure petroleum distillate free from water, heating, and distilling of the water. The weight of the water condensed and collected is expressed as the percentage by weight of the original sample. The allowable maximum water content should not be more than 0.2% by weight.

Bitumen Tests- Loss on heating Test

When the bitumen is heated it loses the volatility and gets hardened. About 50gm of the sample is weighed and heated to a temperature of 163 C for 5hours in a specified oven designed for this test. The sample specimen is weighed again after the heating period and loss in weight is expressed as the percentage by weight of the original sample. Bitumen used in pavement mixes should not indicate more than 1% loss in weight, but for bitumen having penetration values 150-200 up to 2% loss in weight is allowed.

Summary

Requirements of bitumen as a binding material and its different forms were discussed. Various tests are conducted on bitumen to assess its consistency, gradation, viscosity, temperature susceptibility, and safety. Standard test procedures on bitumen were also covered in this chapter.

Problems

The minimum ductility value specified by BIS for bitumen is

- 50 cm

- 25 cm

- 75 cm

- 100 cm

The allowable maximum water content in bitumen should not be more than

- 2% by weight

- 0.2% by weight

- 2.5 % by weight

- 5 % by weight

European Standard CEN Bitumen Tests

TAVOIL’s mission is to promote the efficient, economic, effective and safe use of bitumen. Harmonised standards are the basis for defining the consistent and effective specifications for the supply of bitumen across in the world. TAVOIL contributes to the development of standards and test methods by participation in CEN working groups to ensure that bitumen specifications are fit for purpose. Various fundamental test methods are used for the technical classification and assessment of the different bitumen types which, in the first instance, determine the consistency of the bitumen in different temperature ranges.

ve specifications for the supply of bitumen across in the world. TAVOIL contributes to the development of standards and test methods by participation in CEN working groups to ensure that bitumen specifications are fit for purpose. Various fundamental test methods are used for the technical classification and assessment of the different bitumen types which, in the first instance, determine the consistency of the bitumen in different temperature ranges.

Softening point – Ring and Ball method (EN 1427)

This method, under European standard EN 1427, serves to test the behaviour of bitumen at elevated service temperatures. The temperature is determined at which a layer of bitumen, in a brass ring, experiences a certain deformation under the weight of a steel ball as the temperature rises. This test method has been used for more than one hundred years.

Needle penetration (EN 1426)

A test method that has been used for decades, which is now described in EN 1426. Needle penetration is determined by the depth, measured in 1/10 mm, to which a 100 g needle penetrates in 5 seconds into the bitumen at a temperature of 25 °C. It serves to test the behaviour of bitumen at intermediate service temperatures. This test method is suitable for all types of bitumen.

Penetration Index (EN 1427)

Penetration Index is not a test method as such but obtained by calculation from the Ring and Ball Softening Point and Needle Penetration. The calculation formula is based on the assumption that the penetration of the binder is 800 0,1 mm at its softening point. This is correct for most conventional binders but not for Polymer Modified and special binders. The original calculation was based upon the determination of the needle penetration at different temperatures.

Fraass breaking point (EN 12593)

The determination of the Fraass breaking point is described in the test standard EN 12593. It describes the transition of the binder from a flexible to a brittle condition and provides the temperature at which a thin bitumen layer on a steel sheet cracks during uniform cooling when it is bent under defined conditions. The test indicates the behaviour of the bitumen at low service temperatures.

Elastic recovery (EN 13398)

The test for elastic recovery is applicable to binders modified with elastomers and serves to demonstrate the modification of the binder. The sample is stretched at a fixed temperature and speed to a maximum of 20 cm and then severed. After a prescribed period of time, the degree of elastic recovery is determined relative to the original length.

Force ductility (EN 13589)

The further development of the well-known ductility test serves to determine the cohesive characteristics of a binder, the test is used in the standard for polymer-modified bitumen. A sample is stretched at a fixed temperature and speed and the necessary tensile force is measured and recorded continuously. The data are used, among other things, to calculate the deformation energy, the maximum tensile force or the stretch length of the sample until breakage. Further options for interpretation of the data are currently being researched and discussed.

phase angle – Dynamic Shear Rheometer (DSR) (EN 14770)

The Dynamic Shear Rheometer (DSR) is an instrument which is used to test bitumen properties under a variety of loading conditions and temperatures. The DSR can apply a controlled stress to the sample and measures the response, from which it can calculate properties such as the complex shear modulus G* and phase angle. Testing using the DSR is described in the test method standard EN 14770. Typically, DSR testing is conducted over a range of test temperatures and/or loading frequencies, called temperature and frequency sweep respectively. From the recorded data complex shear modulus G* and its phase angle (δ) at given temperatures/frequencies are calculated.

Multiple Stress Creep and Recovery Test (MSCRT) (EN 16659)

The Dynamic Shear Rheometer (DSR) testing device is also used to perform the Multiple Stress Creep and Recovery Test. This test method is described in the test standard EN 16659and addresses elastic response and sensitivity to permanent deformation of bituminous binders as well as stress dependence. A sample of binder is placed between two parallel plates and loaded with constant stress for exactly 1,0 s, followed by 9,0 s without any load. Ten creep and recovery cycles are conducted, from which the percent recovery and non-recoverable compliance of the binder are calculated. The test uses different stress levels, hence the name; ‘Multiple-Stress Creep and Recovery Test’.

Bending Beam Rheometer (EN 14771)

The Bending Beam Rheometer (BBR) is a device to address the behaviour of bitumen at low service temperatures and is described in the test standard EN 14771. The sample is placed under a constant load in a liquid bath at low temperature for a fixed duration. The creep stiffness of the sample is calculated from the applied stress and resultant strain over time. The test provides information on the stiffness of the binder at low temperatures and its ability to dissipate, or relax, the stress.

Short-Term Ageing: RTFOT-Method (EN 12607-1)

The Rolling Thin Film Oven Test (RTFOT ) is a conditioning process, rather than a test method and is described in EN 12607-1. RTFOT simulates the combined effects of heat and air on a thin film of bituminous binder. The procedure is intended to simulate the ageing that takes place during the mixing and transportation process for hot mixtures. For paving grade binders a reasonable correlation with the bitumen ageing during asphalt mix production is reported. However, the standard conditioning parameters are not necessarily applicable to modified binders, for which the viscosity may be too high to provide a moving film.

Long Term Ageing: Pressure Ageing Vessel (PAV) Method (EN 14769)

As with the RTFOT, the PAV ageing is a conditioning process intended to give information about long-term ageing susceptibility. It is usually carried out after RTFOT-conditioning. Although there are still questions about the applicability of this ageing procedure, due to the prolonged high-temperature experienced by the binder, PAV is the current reference long-term ageing procedure used in Europe & the US and is described in EN 14679. The sample is subjected to high air pressure (2,1MPa), applied to a thin film of bituminous binder under elevated temperature for a given time. PAV ageing is intended to simulate the degree of age hardening that the binder will experience over several years in service.